Pulper

- Efficiently breaks down raw material into pulp slurry.

- Can handle a wide variety of raw materials (wood chips, recycled paper).

- Available in different configurations, such as high-consistency or low-consistency pulpers, depending on the process.

Pulper Impeller

- Designed to provide high agitation and mixing to break down materials.

- Made from durable materials to withstand wear and tear.

- Optimized for maximum fiber separation and consistency.

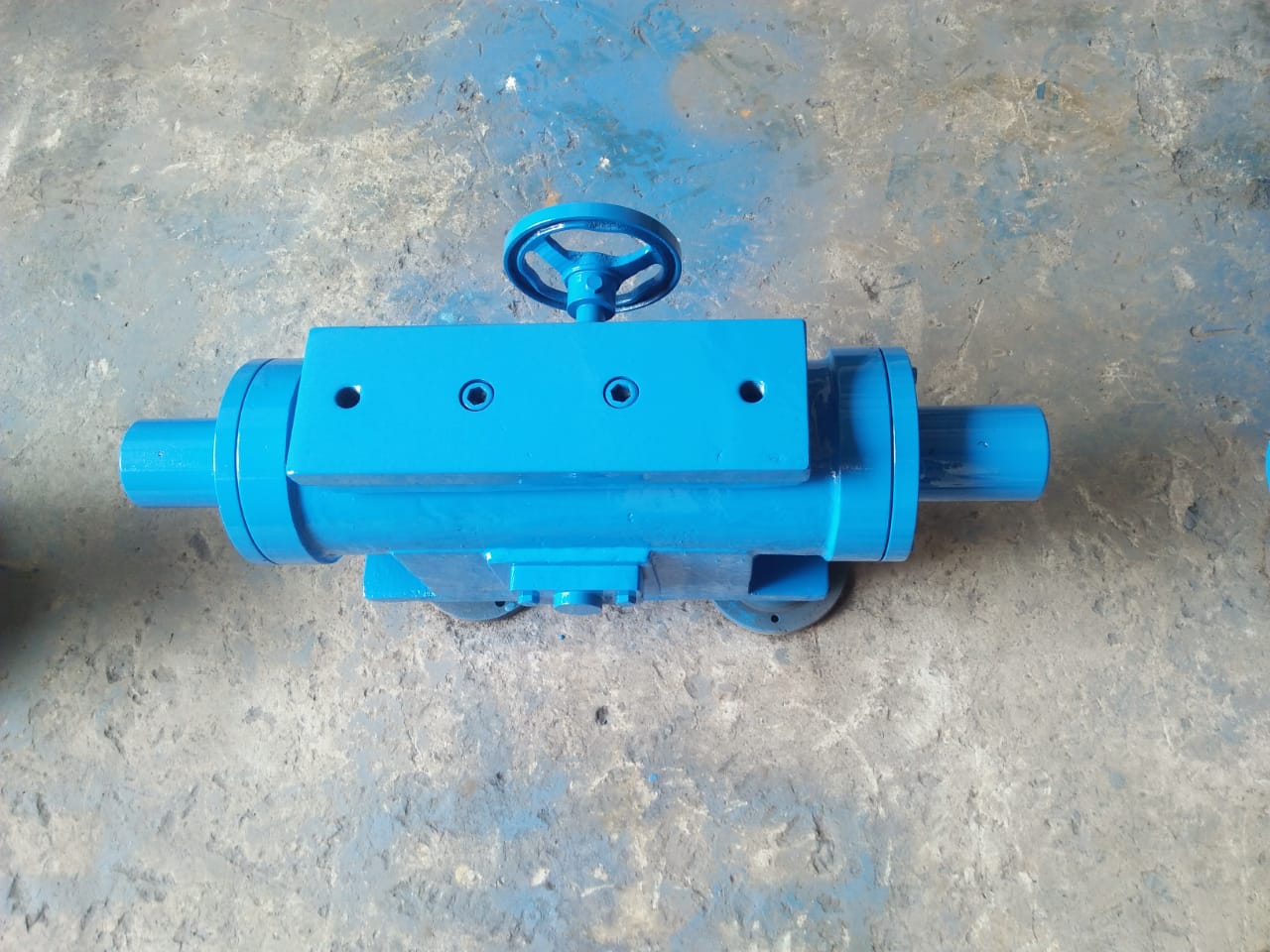

High Density Cleaner

- Removes contaminants like sand, dirt, and plastics from the pulp.

- Uses centrifugal force to separate impurities from the slurry.

- Increases the overall quality of the pulp for downstream processes.

Gravity Cylinder Thickener

- Uses gravity to remove excess water from the pulp.

- Increases pulp consistency, making the pulp more concentrated.

- Reduces water content before the pulp enters the refining or screening process.

Turbo (Fibrizer)

- Breaks down fiber bundles into individual fibers for better pulp quality.

- Increases pulp flexibility and paper strength.

- Helps achieve uniform fiber distribution for smooth paper texture.

Vibrating Screen (Johnson Screen)

- Filters out larger debris and particles from the pulp.

- Provides efficient separation through vibration.

- Allows for high throughput while maintaining consistent quality.

High Pressure Screen

- Removes finer impurities and oversized fibers from the pulp.

- Operates at high pressures to provide efficient filtration.

- Improves the quality of pulp before the paper-making stage.

Centri Cleaner

- Uses centrifugal force to remove fine contaminants from the pulp.

- Increases the cleanliness and quality of the pulp slurry.

- Reduces the risk of equipment damage due to foreign particles.

Thickener

- Increases pulp consistency by removing excess water.

- Prepares pulp for further refining processes.

- Available in multiple designs for different pulp types and processing requirements.

Tri-Disk Refiner (TDR)

- Uses three rotating disks to refine pulp fibers.

- Enhances pulp quality by reducing fiber size and improving uniformity.

- Can handle a variety of raw materials for different types of paper production.

TDR Disk Set (Local & Imported)

- Available in both local and imported versions, catering to different budget needs.

- Designed for durability and high-efficiency refining.

- Can be customized to suit different pulp production requirements.

Chest Pump

- Provides consistent pulp flow from the chest to subsequent processes.

- Designed for high efficiency and low maintenance.

- Ensures accurate pressure regulation for optimal pulp transport.

Chest Agitator

- Mixes the pulp slurry in the chest to maintain even consistency.

- Prevents fiber settling and ensures a uniform pulp flow.

- Helps optimize the transfer of pulp to the next processing stage.